Technocoat TL-series (TL-50/100/200) pulsed laser overlay/ laser welding equipment

The TL-series is made in Japan that promises a high quality and thorough user support system

MADE IN JAPAN

Precision Overlay and Welding of Laser by reliable Japan quality. TechnoCoat TL Series is Made In Japan Laser Overlay & Welding Equipment promises Higher Performance, Lower Cost, and Higher Reliability. Besides, providing full supporting of operational training by high skilled laser welders and maintenance by high skilled engineers to make best performance of the device establishing a Buck-up system for customers.

Details

APPLICATION

INDUSTRIES

FUNCTION

MATERIAL

PRODUCT DESCRIPTION

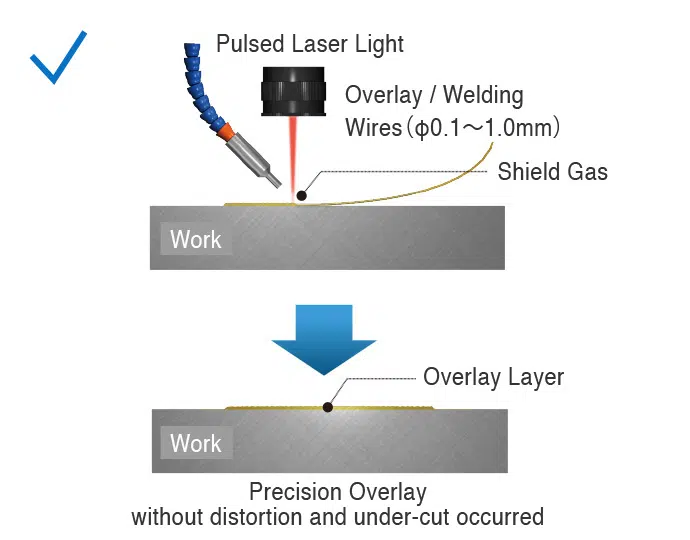

Pulse Spot Irradiation

The overlay material melts instantly and bonds with the base material using a low heat input. This process enables high-quality overlay welding without adverse heat effects, such as distortion or undercutting.

Minimizing Failures like Pinholes and Porosity

Argon gas shielding prevents oxidation in the overlay area, ensuring a higher quality overlay.

Minimizing Overlay Material Usage

Narrow grooves, hole bottoms, side faces, inner faces, and inside corner fillets can be welded effectively without the need for pre-heating or post-heating.

Applicable to Various Steel Types and Dissimilar Metals

Suitable for overlay welding on most steels, including aluminum, titanium, copper alloys, stainless steel (SUS), gold, and even dissimilar metal combinations.

Laser Welding

Laser Welding

Advantages:

Easy operation

Low heat input

Enables precise overlay welding (Reduces finishing time & cost)

Can perform overlay welding in narrow grooves, bottom holes, side faces, inner surfaces, on overlay joints, or inside corners

No need for pre-heating or post-heating

Disadvantages:

Slow overlay process for large areas

Argon Arc Welding (TIG)

Argon Arc Welding (TIG)

Advantages:

Quick overlay

Easy to operate on-site

Disadvantages:

High-skill to operate

High-heat input (Prone to distortion and stress)

Undercut formation

Requires a larger amount of overlay material (Increases finishing time & cost)

Difficult to perform overlay welding in narrow grooves, bottom holes, or side faces

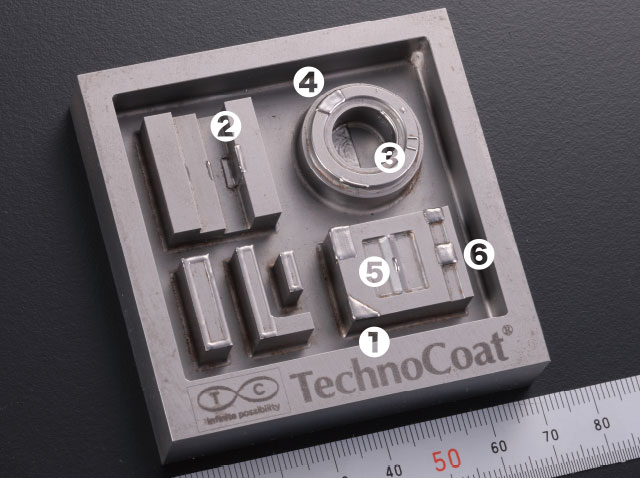

Applications of Overlay Welding and Joining

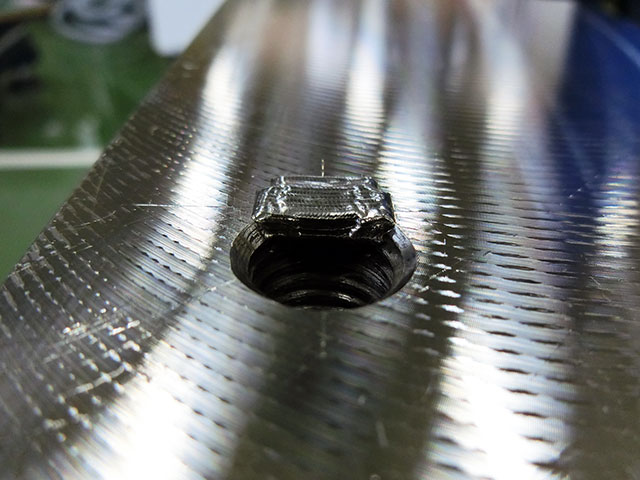

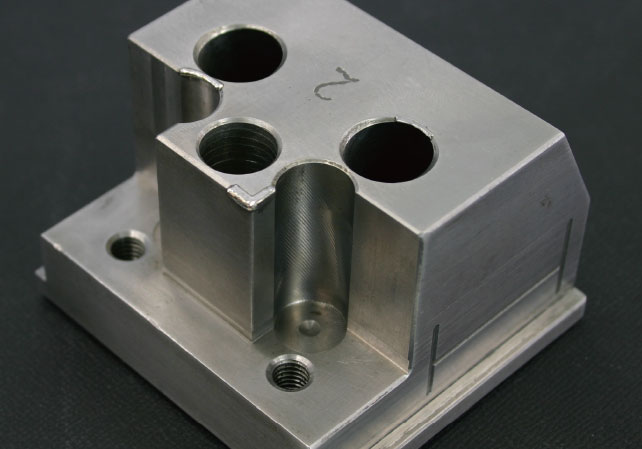

Die & Mold: Overlay repair for plastic injection molds, rubber molds, glass molds, die-casting molds, press molds, and dies.

Machine Parts: Overlay repair for wear parts, cracks, pinholes, and processing defects.

Welding: Repairing under-cut or pinholes caused by the Argon (TIG) welding method.

Precision Parts: Precision overlay welding for various electronic components, sensors, and connectors.

Dissimilar Metals: Overlay and welding for dissimilar metal joining.

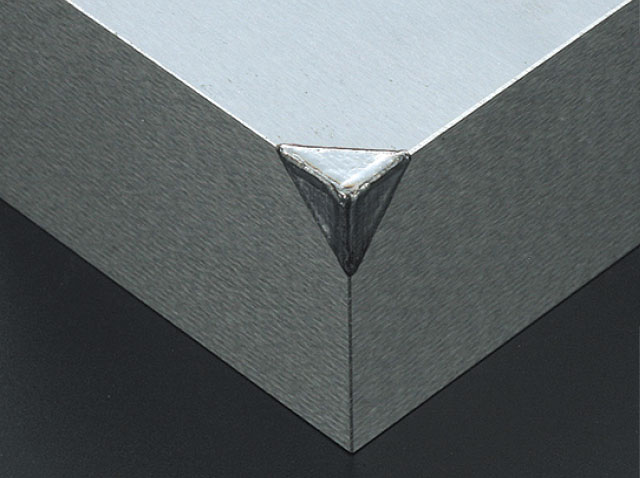

Sheet Metal: Overlay and welding for sheet metals such as titanium (Ti), stainless steel (SUS), and other various metals.

Medical: Overlay and welding for dental techniques and medical equipment.

Marking: Marking on molds, dies, and machinery parts, as well as overlay welding for erasing imprints and engraved letters.

Surface Treatment: Overlay welding for surface treatments such as thermal spraying, plating, or TD processing.

Power Supply Unit

| Model | TL-50 | TL-100 | TL-150 | TL-200 |

| Beam Source | Nd3 + YAG | Nd3 + YAG | Nd3 + YAG | Nd3 + YAG |

| Laser Wavelength | 1064nm | 1064nm | 1064nm | 1064nm |

| Laser Excitation System | Xenon Flash Lamp | Xenon Flash Lamp | Xenon Flash Lamp | Xenon Flash Lamp |

| Average Output | 50W | 100W | 150W | 200W |

| Output Current Amount | 40 to 150A (1A) | 40 to 150A (1A) | 40 to 300A (1A) | 40 to 300A (1A) |

| Pulse Output Time | 0.5 to 15ms (0.1ms) | 0.5 to 16ms (0.1ms) | 0.5 to 20ms (0.1ms) | 0.5 to 20ms (0.1ms) |

| Pulse Frequency | 0.5 to 15Hz (0.1Hz) | 0.5 to 15Hz (mỗi 0.1Hz) | 0.5 to 15Hz (0.1Hz) | 0.5 to 15Hz (0.1Hz) |

| Laser Spot Diameter | 0.2 to 2.0mm | 0.2 to 2.0mm | 0.2 to 2.0mm | 0.2 to 2.0mm |

| Power Supply | AC 200 / 220V (50 / 60Hz) | AC 200 / 220V (50 / 60Hz) | AC 200 / 220V (50 / 60Hz) | AC 200 / 220V (50 / 60Hz) |

| Max. Electric Power Consumption | 2.3kWh | 4.0kWh | 5.0kWh | 6.4kWh |

| Dimension | W380 × L750 × H940mm | W380 × L750 × H940mm | W480 × L650 × H810mm | W480 × L650 × H810mm |

| Weight | 110kg *¹ | 85kg | 110kg | 110kg |

Head Part Revolving

Rotation Angle: ±90°

Microscope

Ocular lens: ×10

Objective lens: ×1

Visual Field Qty: 23 SUPER WIDE FIELD (SWF)

Focal length:

Standard: 150mm

Optional: 80mm / 200mm

Dimension: W110 × L975 × H140mm

Weight: 17kg

Worktable

| Movable Scope: | X250 × Y1300 × L350mm |

| Max. Loading Capacity: | 40kg |

| Dimension: | W500 × L400 × H620mm |

| Weight: | 45kg |

Movable Scope

| Sliding width: | 220mm, Sliding length: 180mm |

| Dimension: | W400 × L850 × H750mm |

| Weight: | 50kg |

Motorized Laser Head Stand

| Movable Scope: | Sliding width: 740mm

X140 × Y130mm × Z600mm Z-axis rotation: ±180° |

| Dimension: | W700 × L700 × H min. 800mm to max. 1300mm |

| Weight: | 70kg |

Chiller

| Model | TL-50 | TL-100 | TL-150 | TL-200 |

| Dimension | W377 × L500 × H815mm | W377 × L500 × H815mm | W377 × L500 × H860mm | W377 × L592 × H976mm |

| Weight | 43kg | 47kg | 47kg | 86kg |

| Cooling Capacity | 1300W (80Hz) | 2400W (80Hz) | 3000W (80Hz) | 5000W (80Hz) |

Accessories

Universal Jig

Universal Jig

Protective Goggles

Wire Holder

Overlay / Welding Wires

Shield

Nipper

Safety equipment

TechnoCoat Laser Overlay / Welding Systems are Class 4 Laser products, and safety measures to prevent damage due to laser light has been decorated.

At the time of use, it is recommended safety management implementation of the class correspondence.

It is able to execute Safety Education and Training relating to the Laser Light according to request.

Protective Filter – Electric Shutter

Equipped with an IR Cut Filter to block infrared light.

Equipped with an IR Cut Filter to block infrared light.

Electric shutter blocks plasma and strong visible light.

Leakage light is inspected using a microscope.

(Inspection equipment: OPHIR Corp. PD300 Sensor)

Shielding Plate

Suppresses reflected light from reaching the operator.

Suppresses reflected light from reaching the operator.

Pilot Lamp (Optional)

Yellow: Stand-By

Yellow: Stand-By

Green: Laser Irradiation

Red: Error (Lighting / Buzzer)

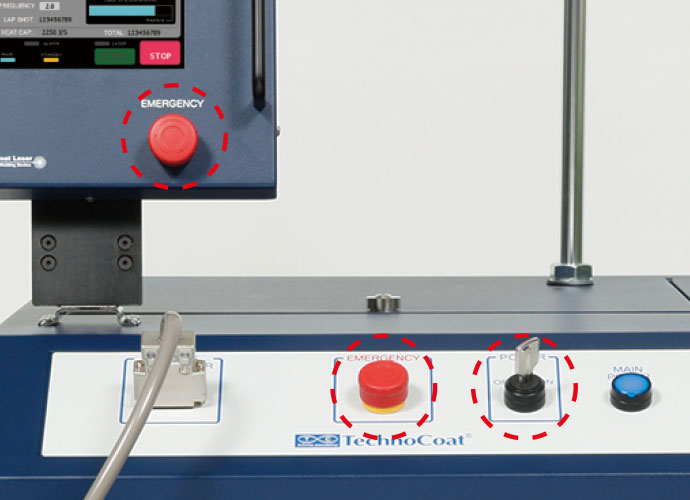

Key Switch / Emergency Stop Button

Operational control using a key switch.

Operational control using a key switch.

Equipped with an emergency stop button for safety

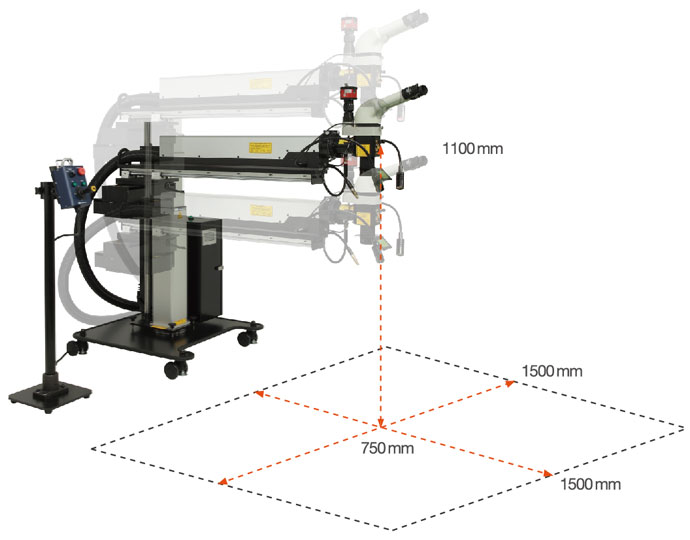

Motorized Workstation

Dimension: W700 × L700 × H min 800mm, max 1300mm

Dimension: W700 × L700 × H min 800mm, max 1300mm

Weight: 87kg

Movement range: X140 × Y130 × Z800mm

Back-and-forth sliding distance: 740mm

Head rotation: ±90°

Z-axis revolution: ±180°

Reference workpiece size: X1500 × Y1500 × Z1100mm

The motorized workstation is capable of three-axis movement, back-and-forth sliding, and Z-axis rotation.

This system allows the laser head to be moved to the desired position using remote control without having to move the workpiece, improving workability on large materials.

Worktable

Movable Scope: X250 × Y130 × Z300mm

Movable Scope: X250 × Y130 × Z300mm

Max. Loading Capacity: 40kg

Dimension: W500 × L400 × H620mm

Weight: 45kg

Description: The worktable has the capability to move along three axes (X, Y, Z), allowing flexible adjustments to suit various applications. Its sturdy design supports a maximum load of up to 40kg, optimizing precision operations.

|

|

|

|

|

|

| CMOS Camera / CCD Camera / Camera Mount

Monitor observation with CCD Camera |

Angle Lens

Rotate: 360° / Angle: 0-40° |

Inclination Microscope

Adjustable angle from 0° to 30° for operator’s physique and head angle |

Zoom Lens

Adjustable zoom lens from x6 to x80 |

Universal Jig

Dimensions: W150mm × H90mm Angl: Fixable at the desired angle Contact Surface: 100mm Magnet type |

Rotational Angular Jig

Dimensions: W142 × L198 × H116mm Angle: Adjustable between 0° and 90° Chuck Rotation: 360° Grippable Size (mm): Outside diameter: 2 đến 55mm Inside diameter: 22 đến 100mm |

TL Series Applications

|

|

|

|

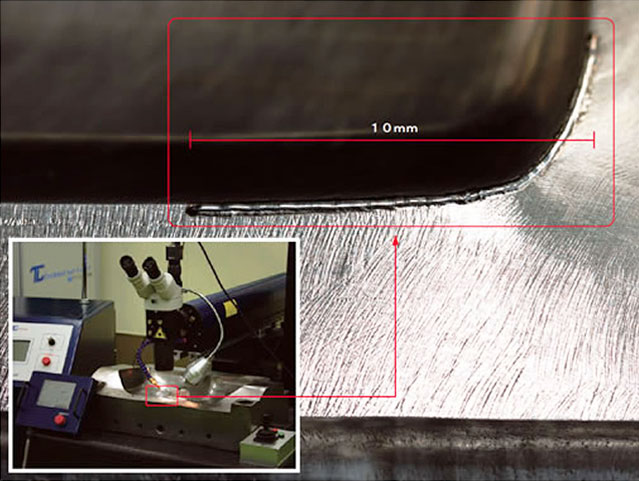

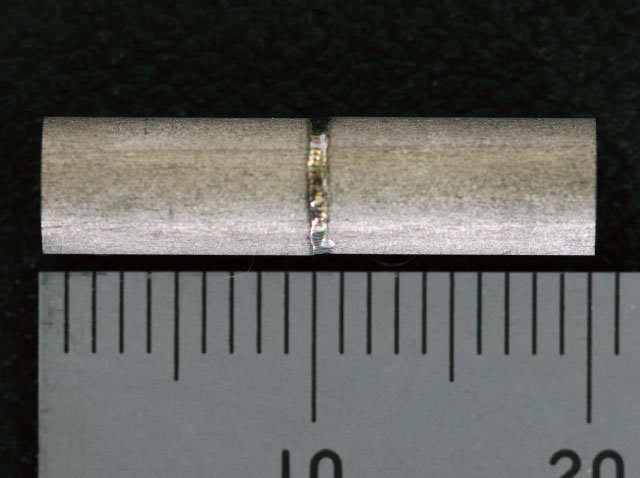

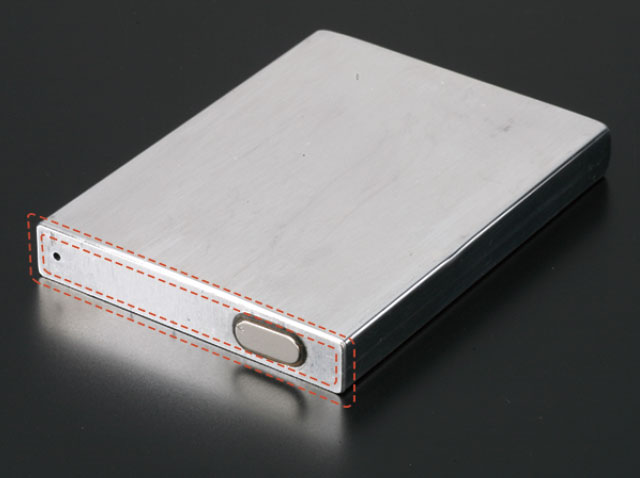

| Overlay repair of erroneous cutting and cutting mistakes | Overlay repairing molds, dies, and mechanical tools | Joint-Pipes | Battery case top part welding |

|

|

|

|

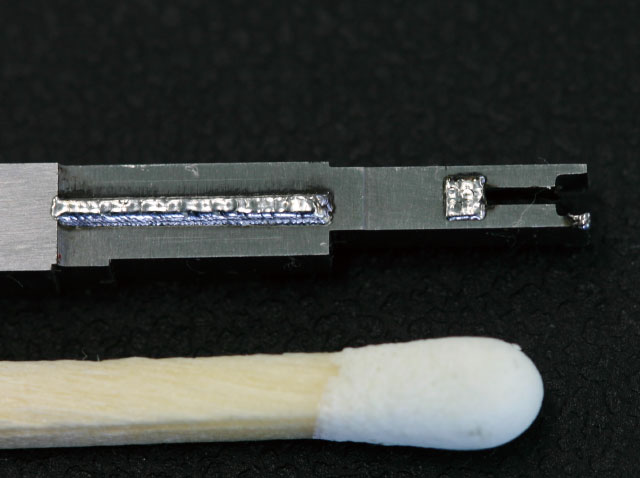

| Overlay – Connector Mold | Overlay – Corner Tip / Overlay-Edge | Repairable Edge / Curved Surface / Bottom Face area | Molds and Dies, Mechanical Parts, and Equipments Overlay Repairing |

RELATED PRODUCTS

see more productsThank for your attention to Technocoat TL-series (TL-50/100/200) pulsed laser overlay/ laser welding equipment. If you need get a quote, please fill in the form bellow & send it to us. We will respond within 24 hours.

If you have any question,

please fill in the form in the right

& send it to us.

We will respond to you in the shortest time.