Technocoat Smart Laser TL-150LDA/300LDA/450LDA

Smart Laser Technocoat

TL-150LDA/300LDA/450LDA

Super precision laser process for manufacturing and repair

Portable and Maintenance Free achieved Lower Running Cost.

New Fiber Laser Overlay / Welding Equipment.

Details

APPLICATION

INDUSTRIES

FUNCTION

MATERIAL

PRODUCT DESCRIPTION

Portable Fiber Laser Overlay / Welding System

Smart Laser

Super precision laser process for manufacturing and repair

Portable and Maintenance Free achieved Lower Running Cost.

New Fiber Laser Overlay / Welding Equipment.

Compact, lightweight, portable, and low maintenance

They have a simple low maintenance structure that requires no chiller and that only uses a few parts that require replacement.

Usable with a variety workpieces

Improved beam quality

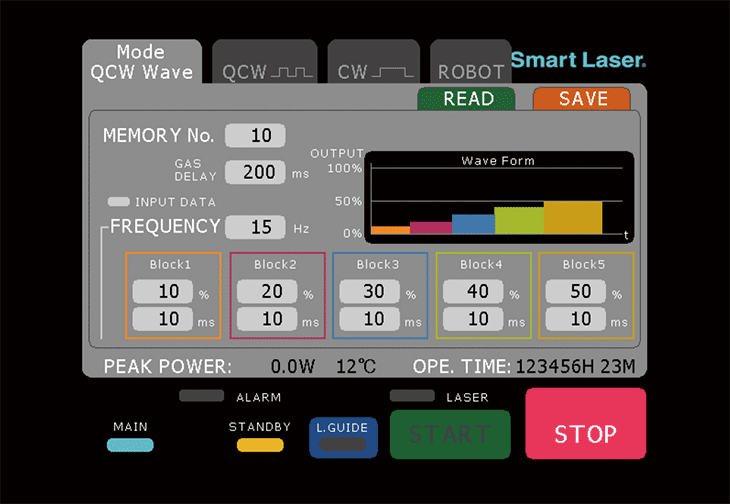

Controlled waveforms capability

They prevent cracking when overlaying high-hardness materials and provide improved weldability of aluminum, copper alloys, and other metals.

Pulsed and continuous waves abilities

Low running costs

(about 1/6).

Smart Laser Applications

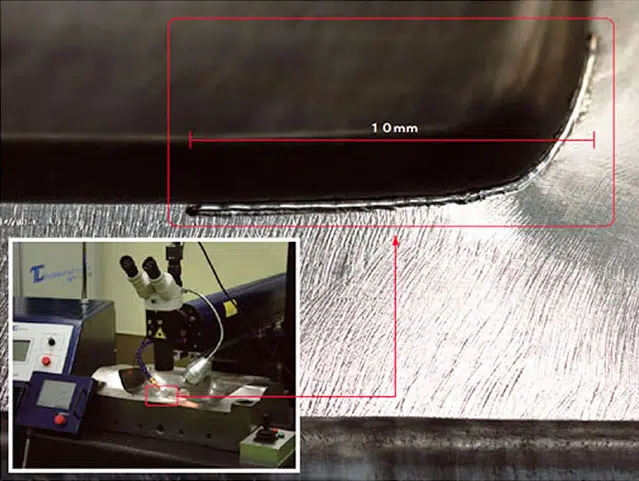

| Overlay Repairing (Small Precision – Huge Work) |

| Spot and Seam Welding (Small / Thin) |

| Overlay and Welding of Dissimilar Metals |

| Overlay and Welding of High Hardness Materials |

| Higher Performance Coating Layer Creation (Laser Coating) |

| Hardening |

| Soldering and Brazing |

Smart Laser System

On-site higher quality repairing is possible for non transportable huge work or not disassemble tools.

| Model | TL-150LDA | TL-300LDA | TL-450LDA |

|---|---|---|---|

| Beam Source | Yb | ||

| Laser Wave Length | 1070nm | ||

| Laser Excitation System | Semiconductor Excitation | ||

| Average Output (Pulse Oscillation) | 150W | 300W | 450W |

| Peak Power | 1.5kW | 3.0kW | 4.5kW |

| Average Output (CW Oscillation) | 250W | 300W | 450W |

| Output Setting | 10% to 100% (per 1%) | ||

| Pulse Output Time | 0.2 to 50ms (per 0.1ms) | ||

| Frequency | CW to 50Hz (1Hz step) *Euipped CW Modulation Mode | ||

| Configurable Max. Joule Amount | 15J / P | 30J / P | 35J / P |

| Laser Spot Dia | dia. 0.1 to 2.0 (Arbitrarily Variable) *When using Overlay Head | ||

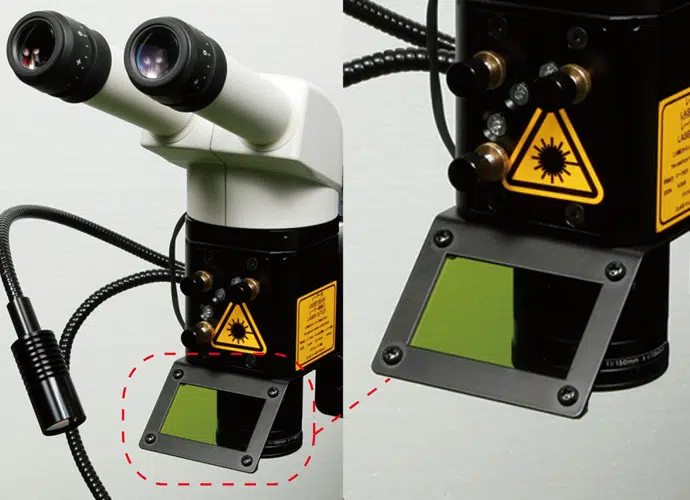

| Microscope | Ocular Lens: ×10 Objective Lens:× 1 Visual Field Qty: 23 SUPER WIDE FIELD (SWF) Focal Length: 150mm (Standard) , 80mm・200mm (Optional) |

||

| Dimension (Power Supply Unit) | W450 × L830 × H860mm (W340 × L680 × H660mm) | W545 × L958 × H990mm | |

| Weight (Power Supply Unit) | 85kg (65kg) | 85kg (68kg) | 130kg |

| Power Supply | Single Phase AC 200V (50 / 60Hz) Allowable Voltage Fluctuation ± 10% |

||

| Max. Electric Power Consumption | 1.2kWh | 1.5kWh | 2.2kWh |

*LDA: Equitable Robot I/O Port and Handy Torch, CW Modulation Mode equipped.

*CW Modulation Mode: Adjustable unit about 2,500Hz max. (Not available on TL-150LD/300LD)

|

|

|

HT10〈for Sheet Metal〉 |

HT20〈for Overlay〉 |

VR Goggles |

| Model | HT10〈for Sheet Metal〉 | HT20〈for Overlay〉 |

|---|---|---|

| Supported Wave Length | 1070nm | |

| Fiber Connector | D 80 | |

| Laser Output | Usable until Ave. 450W | |

| Collimator | dia. 15mm, f 18mm, f36mm AR Coated both sides | |

| Focusing Lends Unit | dia. 15mm, f 100mm AR Coated both sides | |

| Spot dia. = dia. 0.5mm | Spot dia. = dia. 1.0mm | |

| Protective Glass | dia. 15mm, t 1.0mm AR Coated both sides | |

| Dimension | 204 × 40 × 172mm | 204 × 35 × 172mm |

| Weight | About 0.7kg | About 0.65kg |

*Specifications of this product may be changed without notice for improvement of functions etc.

Contact Nam Sơn to receive a detailed quotation and consultation on the right laser solution for your business via hotline

Safety equipment

At the time of use, it is recommended safety management implementation of the class correspondence.

It is able to execute Safety Education and Training relating to the Laser Light according to request.

|

|

|

|

Protective Filter・ Electric Shutter

・Equipped IR Cut Filter shutters Infrared Light

・Electric Shutters shutter Plasma and Strong Visible Light ・Leakage Light inspected from the microscope (Inspection Equip.: OPHIR Corp. PD300 Sensor) |

Shielding Plate・Suppress Reflected Light to Operator

|

Pilot Lamp (Optional)Displaying of Operation State by Light and Sound

・Yellow: Stand-By ・Green: Laser Irradiation ・Red: Error (Lighting / Buzzer) |

Key Switch / Emergency Stop Button・Operational Management by Key Switch

・Equipped with an emergency of Emergency Stop Switch |

Smart Laser Applications

|

|

|

|

| Overlay repair of erroneous cutting and cutting mistakes | Robot Overlay / Welding automation and mass production support | Overlay Repairing Molds, Dies, and Mechanical Tools | Joint-Pipes |

|

|

|

|

| Battery Case Top Part Welding | Overlay – Connector Mold | Overlay – Corner Tip / Overlay-Edge | Repairable Edge / Curved Surface / Bottom Face Area |

|

|

|

|

| Smart Torch (Handy Torch + VR Goggles) | Spot and Seam Welding for Mid and Low Volume Production | Molds and Dies, Mechanical Parts, and Equipments Overlay Repairing |

RELATED PRODUCTS

see more productsThank for your attention to Technocoat Smart Laser TL-150LDA/300LDA/450LDA. If you need get a quote, please fill in the form bellow & send it to us. We will respond within 24 hours.

If you have any question,

please fill in the form in the right

& send it to us.

We will respond to you in the shortest time.