Phased Array Ionizer (High Precision Series) TAS-821 SFS

Phased Array Ionizer (High Accuracy) TAS-821 SFS is a phased array ionizer designed to remove static electricity from conductive surfaces. The static charge in space is completely eliminated with high…

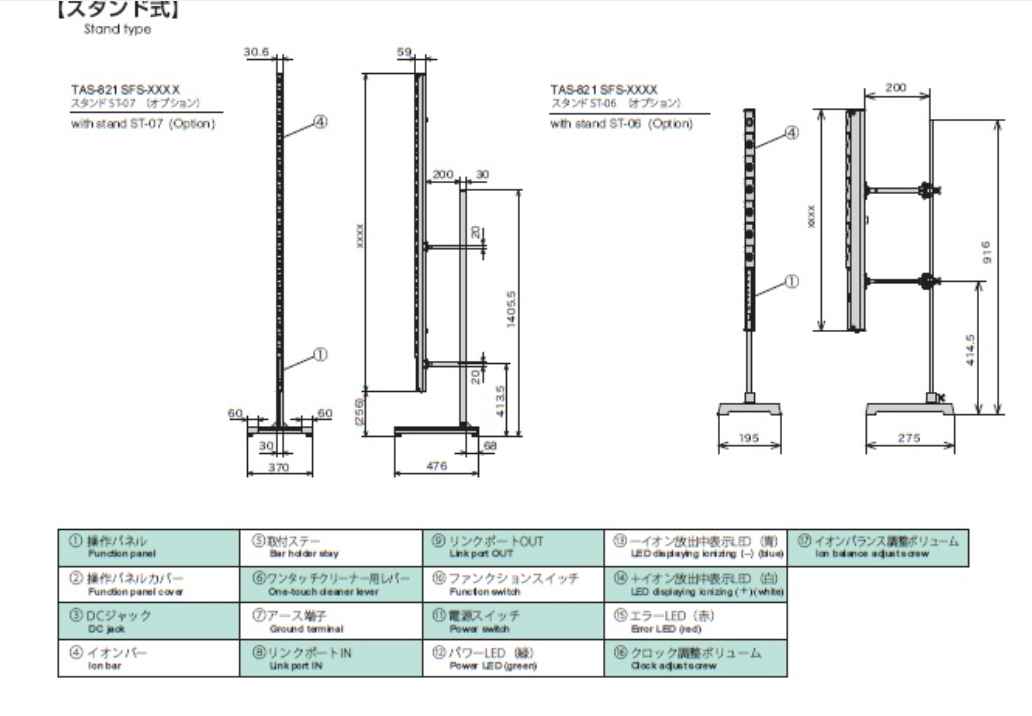

Details

- Eliminates static electricity from PCB panels

- Eliminates static electricity from electronic components

- Eliminates static electricity from electronic devices

APPLICATION

INDUSTRIES

FUNCTION

MATERIAL

PRODUCT DESCRIPTION

Phased Array Ionizer (High Accuracy) TAS-821 SFS is a phased array ionizer designed to remove static electricity from conductive surfaces.

The static charge in space is completely eliminated with high precision. Used in anti-static and anti-impurity measures in the electronics and medical fields.

Outstanding features

High precision: The TAS-821 SFS uses advanced phased array technology to create a highly accurate ion beam. This effectively removes static electricity from small and complex surfaces.

High performance: The TAS-821 SFS machine can process large surfaces in a short time. This helps increase productivity and efficiency of the production process.

Functions and fields:

- Creates an environment free of static electricity.

- FPD (Flat Panel Display) panel conveyor.

- Consumer electronics.

- Equipment assembly line

- Production of panels and films.

- Glass factory.

- Printing factory.

- The process of painting.

- Food factory.

- Pharmaceutical factory.

- Clean room changing room

- Factory producing powder products.

- Plastic factory.

- Textile products factory.

- Packaging factory.

- Hospitals, offices, hotels.

Contact Nam Sơn to receive a detailed quotation and consultation on the right laser solution for your business via hotline

Creates an environment where dust does not adhere to objects by eliminating dust’s static electricity.

Realizing a clean room without walls. All dust and particles lose static electricity.

“Why does dust stick to the product?” TRINC has focused on this fundamental question and analyzed its adhesion mechanism. As a result, we discovered that it was charged dust (activated dust) that adhered to the product. In other words, dust adhesion can be avoided by eliminating static electricity on dust deposited in space. We must avoid blowing air because it disperses dust and particles around. From here, TRINC’s idea of ”Clean room without walls = Clean room without walls” was born.

RELATED PRODUCTS

see more productsThank for your attention to Phased Array Ionizer (High Precision Series) TAS-821 SFS. If you need get a quote, please fill in the form bellow & send it to us. We will respond within 24 hours.

If you have any question,

please fill in the form in the right

& send it to us.

We will respond to you in the shortest time.