Laser Water Jet Cutting machine LCS 800

Main applications include machining of semiconductor equipment sub-assemblies, metal masks and other components made of metal, ceramics or composites (e.g. silicon carbide, CFRP).

Details

- Cylindrical beam resulting in parallel kerfs (no V shape)

- Cutting of 10 mm CBN in 26.5 mm/min.

- No focus control necessary due to long working distance

APPLICATION

INDUSTRIES

FUNCTION

MATERIAL

PRODUCT DESCRIPTION

Precise Laser Cutting System for Large Components

The 3-axis laser cutting machine LCS 800 with integrated Laser MicroJet® technology is a robust and versatile system conceived for a multitude of high-precision cutting and drilling applications in different industrial sectors. The large mounting table allows processing of virtually any part size and is suited for small series and prototypes but also for large volumes. Main applications include machining of semiconductor equipment sub-assemblies, metal masks and other components made of metal, ceramics or composites (e.g. silicon carbide, CFRP).

The LCS 800 has an intuitive and fully integrated system control interface with touchscreen functionality. The offset calibration system integrates automatic laser-nozzle alignment, automatic jet angle correction (both optional) and laser power control

Contact Nam Sơn to receive a detailed quotation and consultation on the right laser solution for your business via hotline

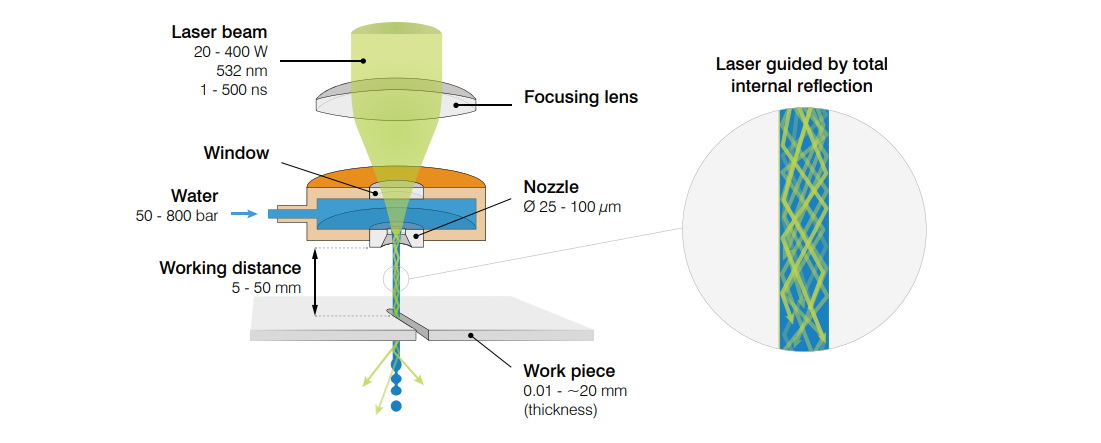

Synova Laser MicroJet® Technology

The Laser MicroJet® is a hybrid method of machining, which combines a laser with a “hair-thin” water jet that precisely guides the laser beam by means of total internal reflection in a manner similar to conventional optical fibers. The water jet continually cools the cutting zone and efficiently removes debris.

As a “cold, clean and controlled laser”, Synova’s LMJ technology resolves the significant problems associated with dry lasers such as thermal damage, debris deposition, taper and lack of accuracy.

Materials

Ceramics & Composites: Silicon carbide (SiC), silicon nitride (SiN), ceramic-matrix composites (CMCs), CFRP, Zirconia (ZrO2), HTCC/LTCC, aluminium nitride (AlN), aluminium oxide (Al2O3)

Metals: Stainless steel, aluminum, copper, nickel, titanium, superalloys, etc.

Ultra-hard materials: Polycrystalline CBN (PcBN), polycrystalline diamond (PCD), single crystalline diamond (SCD), CVD diamond, natural diamond, tungsten carbide (WC)

Operations

2D cutting, drilling, slicing, slotting, grooving, trenching, milling, engraving, profiling

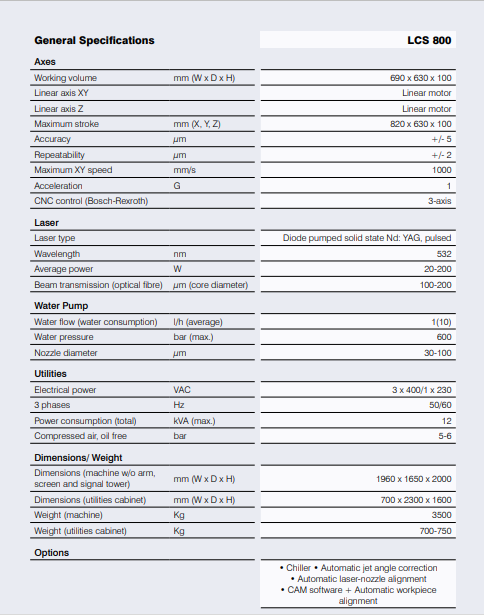

Specifications

RELATED PRODUCTS

see more productsThank for your attention to Laser Water Jet Cutting machine LCS 800. If you need get a quote, please fill in the form bellow & send it to us. We will respond within 24 hours.

If you have any question,

please fill in the form in the right

& send it to us.

We will respond to you in the shortest time.