Laser Water Jet Cutting machine LCS 50

This machine is designed for machining industrial diamond tools and other small parts requiring precision cutting, drilling, grooving or slicing.

Details

- Smooth cutting surfaces and sharp edges (Ra as low as 0.15 µm)

- Finish cutting of 1.6 mm PCD and cemented carbide in 5 mm/min

- No or very little post treatment required

APPLICATION

INDUSTRIES

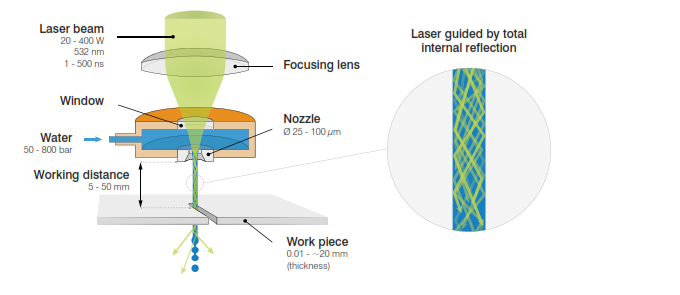

FUNCTION

MATERIAL

PRODUCT DESCRIPTION

High Precision Laser Cutting System

The LCS 50 is Synova’s most compact and cost-effective MicroJet® Laser Cutting Machine (LMJ). This machine is designed for machining industrial diamond tools and other small parts requiring precision cutting, drilling, grooving or slicing.

The machine uses linear motor axes (LCS 50-3) for 3D cutting and shaping, combined with additional torque B and C rotary axes (LCS 50-5) to enable 3D shaping more complex

The state-of-the-art CNC machine system includes a high-power green laser, a compact high-pressure water pump with an ultra-pure water unit, a 21.5-inch touch screen control panel and a monitoring system. close to automatic zoom.

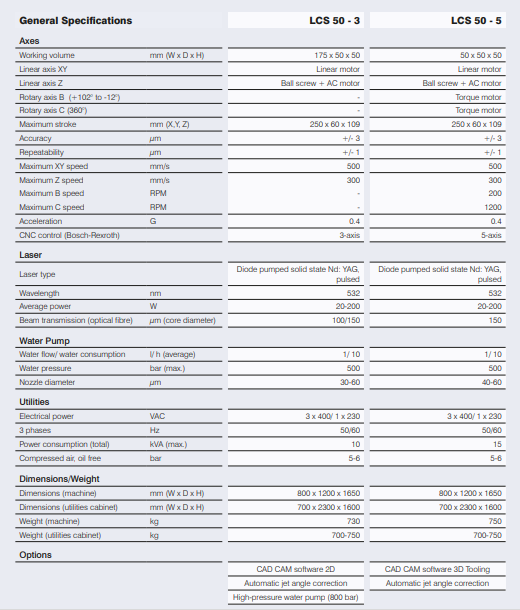

Specifications

RELATED PRODUCTS

see more productsThank for your attention to Laser Water Jet Cutting machine LCS 50. If you need get a quote, please fill in the form bellow & send it to us. We will respond within 24 hours.

If you have any question,

please fill in the form in the right

& send it to us.

We will respond to you in the shortest time.