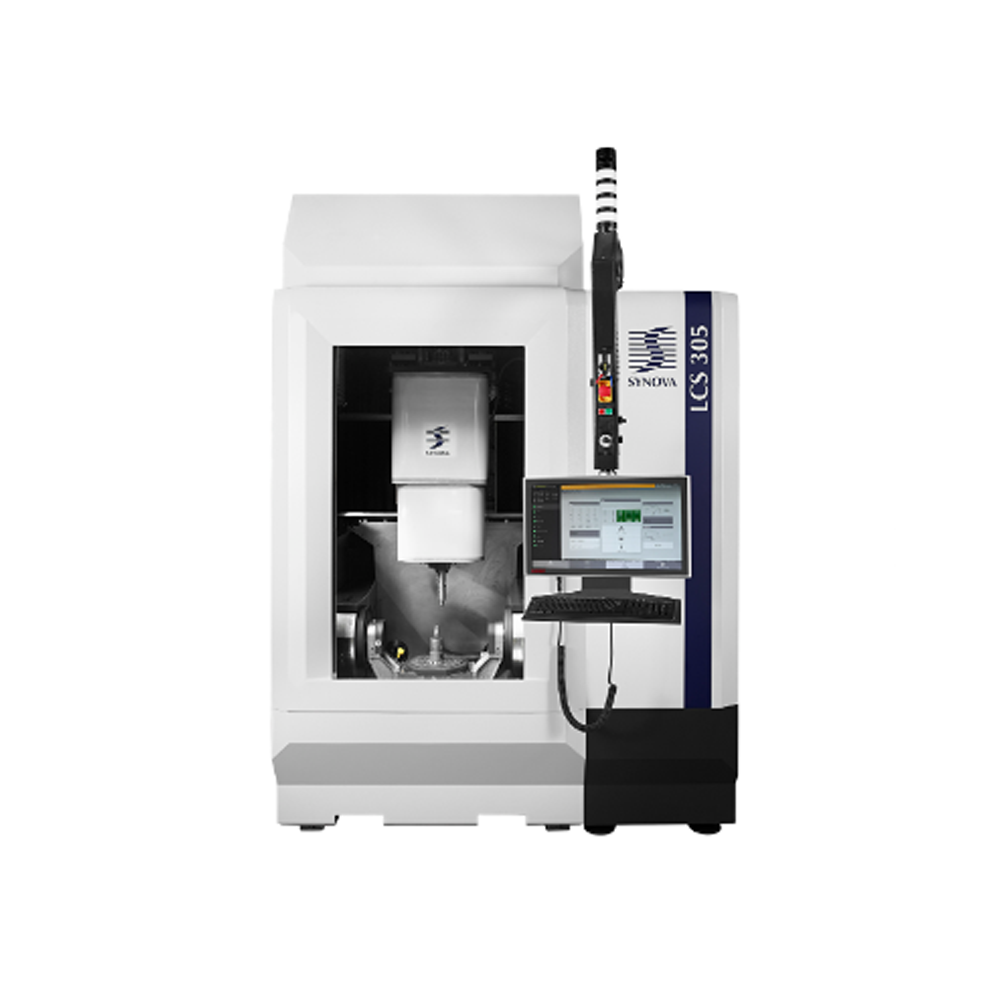

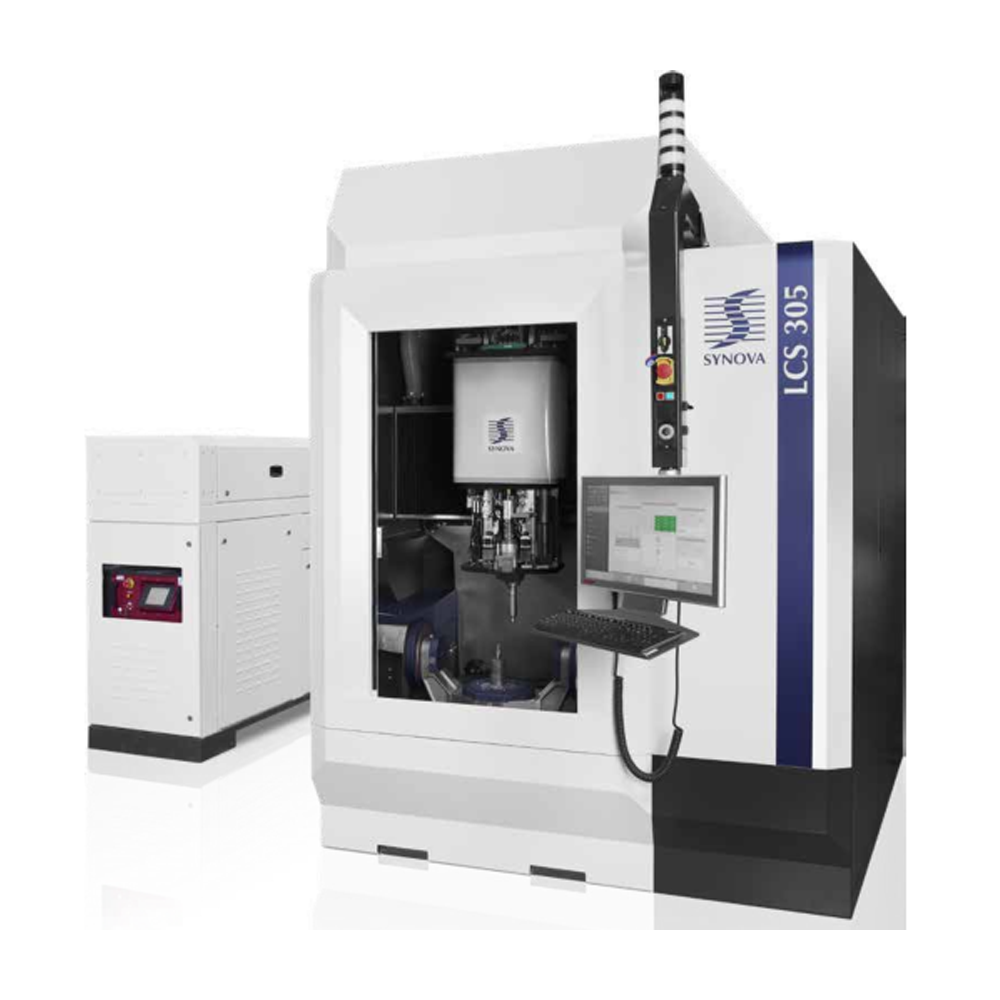

Laser Water Jet Cutting machine LCS 305

Fully automatic offset calibration system integrates laser nozzle alignment, automatic jet angle calibration, laser power meter and touch probe.

Details

- Smooth cutting surfaces and sharp edges (Ra as low as 0.2 µm)

- Finish cutting of 1.6 mm PCD and cemented carbide in 3 mm/min

- Clean surfaces and no deposi-tions

APPLICATION

INDUSTRIES

FUNCTION

MATERIAL

PRODUCT DESCRIPTION

Highly dynamic 5-axis Laser machining center

The LCS 305 with integrated waterjet guided laser technology (Laser MicroJet®) is specifically designed for the automated production of large and small diamond cutting tools. The five-axis synchronous CNC machine is characterized by a particularly intelligent machine concept and highly kinematic axes for maximum precision and speed.

LCS handles consistent temperature control with a water-cooled linear and torque motor (+/- 0.1°C) and a mineral molding platform for greater stability and reduced vibration. Fully automatic offset calibration system integrates laser nozzle alignment, automatic jet angle calibration, laser power meter and touch probe. Tools can be exchanged with very high precision thanks to the HSK 63 tool holder.

Contact Nam Sơn to receive a detailed quotation and consultation on the right laser solution for your business via hotline

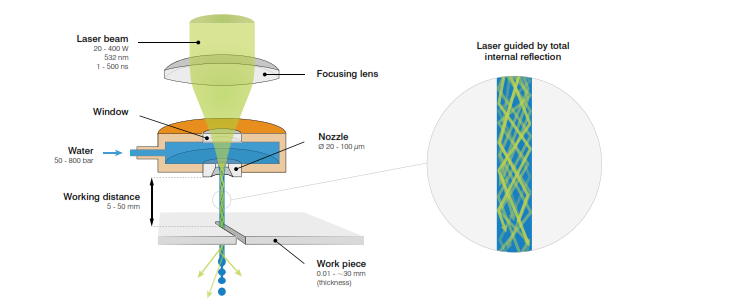

Synova Laser MicroJet® technology

The MicroJet® laser is a hybrid machining method that combines a laser with a “hair-thin” water jet that precisely guides the laser beam by total internal reflection in a manner similar to conventional fiber optics. The water jet continuously cools the cutting area and effectively removes debris.

As a “cold, clean and controlled laser,” Synova’s LMJ technology addresses key issues associated with dry lasers such as heat damage, debris deposition, taper and lack of precision.

Materials

Hard materials: polycrystalline CBN (PcBN), polycrystalline diamond (PCD), single crystal diamond (SCD), chemical vapor deposition diamond (CVD), natural diamond (ND), carbide Tungsten (WC)

Metal: Super alloy, stainless steel, aluminum, copper, titanium, nickel, etc.

Ceramics: Ceramic matrix composites (CMC), silicon carbide (SiC), silicon nitride (SiN), zirconia (ZrO2), HTCC/LTCC (high and low temperature co-fired ceramics), aluminum nitride (AlN), aluminum oxide (Al2O3)

Work

3D cutting, shaping, drilling, slotting, grooving, trenching, milling, slicing, edge grinding (K-land edge, single or multiple open corners), engraving, shaping

Crisp and smooth

- Smooth cutting surface and sharp edges (Ra as low as 0.2 µm)

- Cylindrical beam produces parallel cuts (not V-shaped)

- There is virtually no thermal impact thanks to water jet cooling

Quickly and accurately

- Finish cutting 1.6 mm PCD and cemented carbide at a speed of 3 mm/min.

- High mechanical precision with +/- 5 µm tolerance

- Very small groove width (down to 30 µm

Cleans easily

- Clean surface and no residue

- No post-treatment required

- No need for focus control due to long working distance

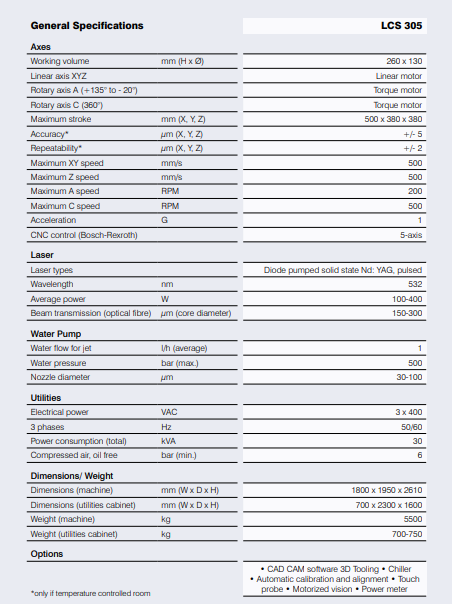

Specifications

RELATED PRODUCTS

see more productsThank for your attention to Laser Water Jet Cutting machine LCS 305. If you need get a quote, please fill in the form bellow & send it to us. We will respond within 24 hours.

If you have any question,

please fill in the form in the right

& send it to us.

We will respond to you in the shortest time.