Laser Water Jet Cutting machine LCS 303

The machine with a working area of 300 x 300 mm uses linear motor axes. The work piece is fixed on a T-Nut table. An optional B rotary axis can be mounted on the table allowing to position the work piece with a different rotation angle.

Details

- Smooth cutting surfaces and sharp edges (Ra as low as 0.15 µm)

- Cutting of 4 mm CVD dia-mond in 5 mm/min.

- Clean surfaces and no depositions

APPLICATION

INDUSTRIES

FUNCTION

MATERIAL

PRODUCT DESCRIPTION

Laser Water Jet Cutting machine LCS 303

The 3-axis LCS 303 with water jet guided laser technology (Laser MicroJet®) is a highly accurate and reliable laser

cutting system. It can process a wide variety of materials, from metals to ultra-hard and brittle materials such as diamond or ceramic, to complex composites. Applications include high precision machining of watch components, medical devices and tools, electronic and other high-tech parts.

The machine with a working area of 300 x 300 mm uses linear motor axes. The work piece is fixed on a T-Nut table. An optional B rotary axis can be mounted on the table allowing to position the work piece with a different rotation angle. The state-of-the-art CNC machine system includes a high-power green laser, a compact high pressure water pump with an ultra-pure water unit, a touch-screen control panel and a vision system with motorized zoom. The automated offset calibration system integrates laser-nozzle alignment, jet angle correction, laser power measurement and jet stability control (all optional).

Contact Nam Sơn to receive a detailed quotation and consultation on the right laser solution for your business via hotline

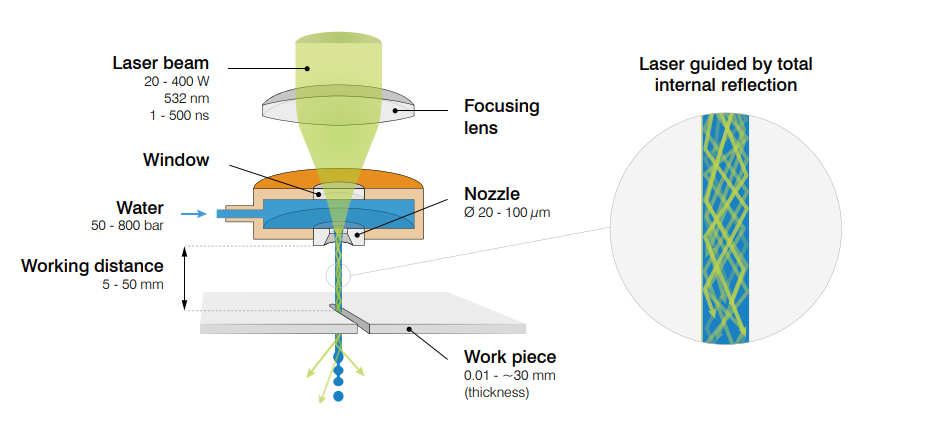

Công nghệ Synova Laser MicroJet®

The Laser MicroJet® is a hybrid method of machining, which combines a laser with a “hair-thin” water jet that precisely guides the laser beam by means of total internal reflection in a manner similar to conventional optical fibers. The water jet continually cools the cutting zone and efficiently removes.

The water jet continuously cools the cutting area and effectively removes parts. As a “cold, controlled laser,” Synova’s LMJ technology addresses key issues associated with dry lasers such as heat damage, debris mitigation, taper and lack of true precision.

Materials & Operations

Metals: Stainless steel, Durnico, Phynox, CuBe, copper, brass, gold, aluminium, shape-memory alloys (Nitinol, cobalt-chrome), titanium, nickel, superalloys etc.

Ultra-hard materials: Polycrystalline CBN (PcBN), polycrystalline diamond (PCD), single crystalline diamond (SCD), CVD diamond, natural diamond, tungsten carbide (WC).

Ceramics & Composites: Silicon carbide (SiC), silicon nitride, (SiN), ceramic-matrix composites (CMCs), CFRP, Zirconia, (ZrO2), HTCC/LTCC, aluminium nitride (AlN), aluminium oxide (Al2O3).

Operations

2D cutting, drilling, slicing, slotting, grooving, trenching, milling, engraving, profiling.

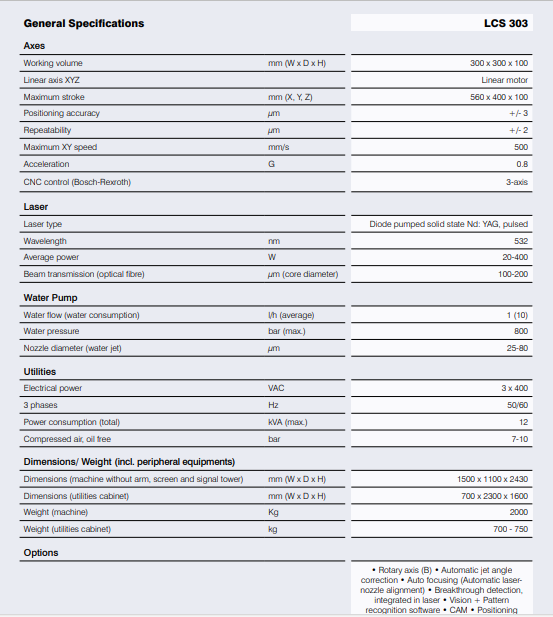

Specifications

RELATED PRODUCTS

see more productsThank for your attention to Laser Water Jet Cutting machine LCS 303. If you need get a quote, please fill in the form bellow & send it to us. We will respond within 24 hours.

If you have any question,

please fill in the form in the right

& send it to us.

We will respond to you in the shortest time.