Laser mold texturing system MLA6050 – MLA3030

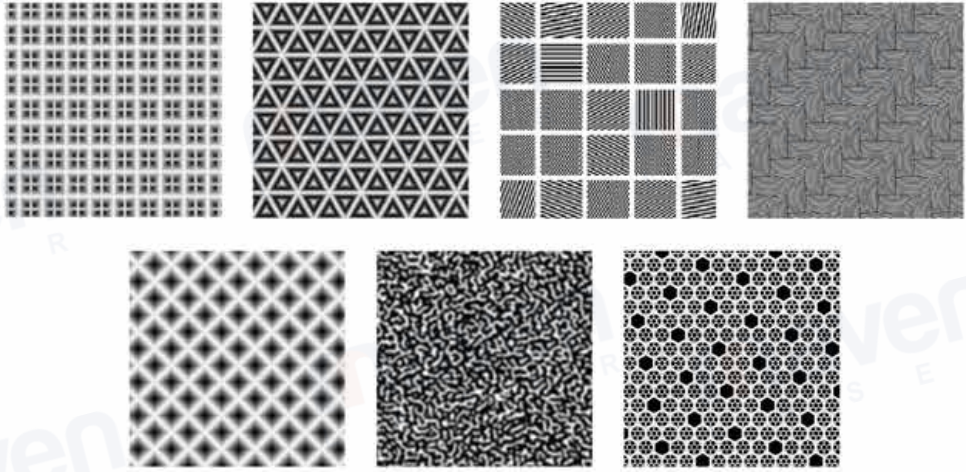

Laser texturing technology has brought an innovative revolution to mold surface processing! From digital computer design to generation program, the fidelity of any graphic texture can be guaranteed by laser processing (the finest can reach 3um).With laser Technology used for ultra-fine processing to make the texture design more variety and achievable. Laser Texturing is enlarging your design imagination come true to the products!

Details

APPLICATION

INDUSTRIES

FUNCTION

MATERIAL

PRODUCT DESCRIPTION

Laser texturing technology has brought an innovative revolution to mold surface processing! From digital computer design to generation program, the fidelity of any graphic texture can be guaranteed by laser processing (the finest can reach 3um).With laser Technology used for ultra-fine processing to make the texture design more variety and achievable. Laser Texturing is enlarging your design imagination come true to the products!

Product Advantages

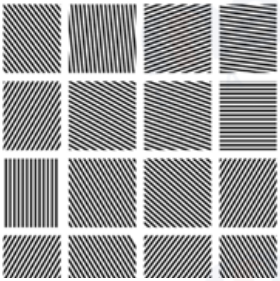

- High precision control, small subdivision angle, and fine texture;

- Automatic compensation, high drop machining;

- Large format texture consistency, seamless splicing;

- Smooth operation of image files within 200G;

- Supports importing STP, STL, OBJ, IGS, PLY, vector images, bitmaps, and grayscale images;

- Configure optical instruments, mold positioning does not require manual repeated adjustments;

- Easy to operate, flexible and easy to understand.

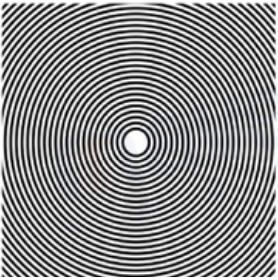

Equipment parameters

| Model | / | MLA6050 | MLA3030 |

| Size | mm | 2260*2140*2600 | 1200*1150*2285 |

| Weight | kg | 6000 | 1250 |

| X/Y/Z axis travel | mm | 700/480/280 | -/-/450 |

| Maximum power | kw | 4.8 | 2.5 |

| Axis type | / | Line code control | Servo control |

| Electricity demand | / | Single-phase 220V50HZ | Single-phase 220V50HZ |

| Water and gas demand | / | Distilled water/0.6MPA | Distilled water/0.6MPA |

| Maximum machining size | /mm | 500*400*250(Single workstation) | 300*300*400(Single workstation) 600*450*410(Multiple workstations) |

| Maximum texture difference | mm | 30 | 50 |

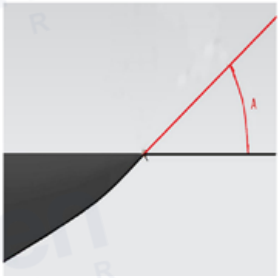

| Maximum angle between textures | ° | 45 | 45 |

| Maximum load | kg | 150 | 500 |

| Laser power | w | 20/50/100 | 20/50/100 |

Series texture machine

It is a star product specially designed by the company for texture processing, with simple operation, professional design, complete system, and high-end configuration.

Product Features

- High Efficiency: Pattern textures can be quickly imported

- High Accuracy: Marble structure&grinding grade lead screw

- High Suitability: Suitable for all mold metal materials

- High Cost Performance: Marble structure&grinding grade lead screw

- High Quality: Micron level laser stable output

- High Flexibility: Ultra flexible algorithms and systems

Laser Texture Technological Breakthrough

|

|

|

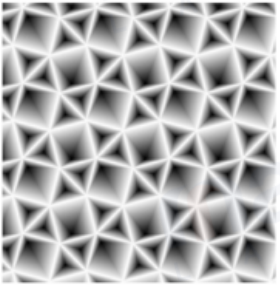

| The intelligent splicing function can process large workpieces, process more complex curved surfaces, and perfectly avoid blind spots | The amazing fine-grain processing technology is far beyond the reach of chemical etching, eliminating traditional difficulties and perfectly solving pain points | Simple and versatile digital operations release unlimited possibilities in design, giving full play to your creativity and allowing you to achieve product differentiation |

|

|

|

| A larger marking range reduces machine tool movement and improves work efficiency and processing quality | Easier to operate, easy to understand and proficient in perfectly reproducing historical works, minimizing the impact of human factors on the product. | Compared with flat surfaces, it has a larger curved surface angle and is suitable for more products. There are more choices in applications |

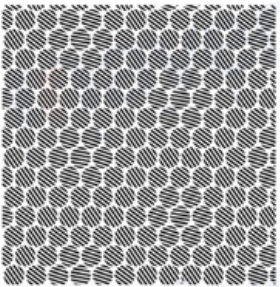

Excellent processing quality

The self-developed intelligent segmentation algorithm V3.0 can intelligently analyze product texture characteristics, intelligent segmentation trajectories, intelligently optimize

processing technology effects, and intelligently optimize processing efficiency. With an integrated marble bed and a 20-bit high-resolution digital galvanometer, it can provide Provide customers with excellent product processing quality.

Operation Process

- Model building: We use simple and easy-to-understand software to export the 3D model of the workpiece and extract the areas that need to be processed

- Graphics processing: Planarize the extracted graphics (which may be curved surfaces); through simple operations, nest the texture pictures into the extracted graphics according to the required proportions to form the required texture model.

- Trajectory formation: According to the processing requirements, the relevant parameters required to design the target texture, such as the number of layers and blocks, are automatically formed into module files.

- Device Presets: Perform benchmark calibration of the equipment (formed once, no need to repeat this operation later) to determine the laser benchmark; use a simple and intuitive way to position the workpiece.

- Processing operations: Confirm all preparations before processing, and the software can be operated with one click, which is simple and easy to understand; the processing process automatically generates a log for easy monitoring.

Product Application

Application areas

|

|

|

|

|

| 3C field | Mold industry | Automobile industry | Tire field | Other specialized field |

Industry scenes

RELATED PRODUCTS

see more productsThank for your attention to Laser mold texturing system MLA6050 – MLA3030. If you need get a quote, please fill in the form bellow & send it to us. We will respond within 24 hours.

If you have any question,

please fill in the form in the right

& send it to us.

We will respond to you in the shortest time.