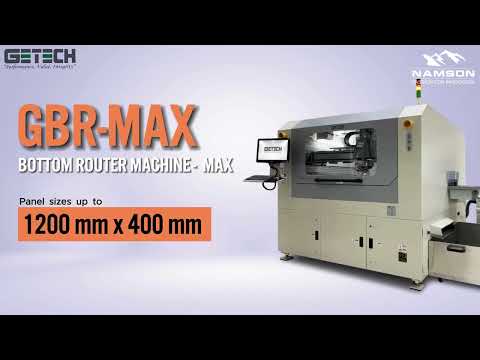

GBR BOTTOM ROUTER MACHINE

The GBR machine is an automated integrated bottom milling system that does not require separate clamps for each type of PCB. The machine is specially designed to mill (separate) large-sized PCB panels, up to 600 mm x 400 mm in size into individual circuit boards.

Details

- Fixture – Less router

- High Accuracy & Quality cut

- In-line Automation ready

- High – speed routing & throught

- Automation tool change and tool mesurement

- Automatic PCB gripper change

- High – resolution camera

APPLICATION

INDUSTRIES

FUNCTION

MATERIAL

PRODUCT DESCRIPTION

The detailed information

The GBR machine is an in-line automated bottom routing system that does not require the addition of PCB-specific fixture systems. It is specially designed to route (depanelize) large panels with PCB sizes up to 600 mm x 400 mm into individual units.

The PCB panels enter the machine through a conveyor. After barcode verification, the conveyor, gripper axis, and bottom spindle router work together to route boards with high stiffness and accuracy. The routed PCBs are subsequently transported via gripper to a wide variety of PCB handling solutions, such as flat belt conveyor, bridge axis, pallet/tray conveyor, dust cleaner, board flipper, and other solutions.

Using a high-resolution CCD camera and user-friendly Windows-based software allows users to program the routing paths in minutes. There are also no limitations on the number of programs stored. GBR uses high-quality components and a welded steel structure to ensure rigidity and high performance. All the axes and linear guides are protected from dust and dirt to increase lifespan and performance.

Contact Nam Sơn to receive a detailed quotation and consultation on the right laser solution for your business via hotline

Advantages of the product

– Fixture – Less router

– High Accuracy & Quality cut

– In-line Automation ready

– High – speed routing & throught

– Automation tool change and tool mesurement

– Automatic PCB gripper change

– High reliablity PCB gripping system

– High – resolution camera

– Powerful dual vacuum system

– CE Certification

Advantages of the product

Video

RELATED PRODUCTS

see more productsThank for your attention to GBR BOTTOM ROUTER MACHINE. If you need get a quote, please fill in the form bellow & send it to us. We will respond within 24 hours.

If you have any question,

please fill in the form in the right

& send it to us.

We will respond to you in the shortest time.