Depo Series – Digital SparkDepo

Advanced Electro-Spark Deposition System for Precision Coating and Overlay

The Digital SparkDepo from TechnoCoat Co., Ltd. represents a cutting-edge solution in preventive maintenance and repair for machine parts, molds, and dies. Utilizing the principles of Electrical Discharge Machining (EDM), this system delivers high-quality coatings and overlays with exceptional bonding strength and minimal thermal impact.

Details

APPLICATION

INDUSTRIES

PRODUCT DESCRIPTION

Key Features:

-

High Bonding Strength Mechanism: Employs rapid discharge of direct current, heating electrode materials to 8,000–25,000℃, transforming them into plasma that metallurgically bonds with the workpiece surface. This process ensures a robust diffusion layer akin to grown roots, providing superior adhesion.

-

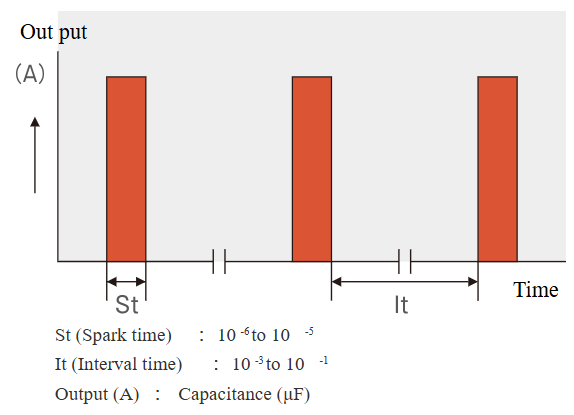

Low Heat Input: The ultra-short spark duration (10⁻⁶ to 10⁻⁵ seconds) compared to the interval time prevents heat accumulation, eliminating distortion, shrinkage, pinholes, or stress during diffusion and deposition.

-

Versatile Material Compatibility: Suitable for a wide range of substrates, including low and medium carbon steels, tool steels, die and mold steels, cast steels, stainless steels, aluminum alloys, copper alloys, and most electrically conductive alloys and composites.

-

On-Site Workability: Portable design allows for on-site processing without the need to disassemble large equipment. Repairs can be conducted directly on the necessary parts, significantly reducing downtime and improving work efficiency.

-

Adjustable Coating Parameters: The thickness and surface roughness of the coating layer can be precisely controlled by adjusting output and frequency, allowing for tailored processing as intended.

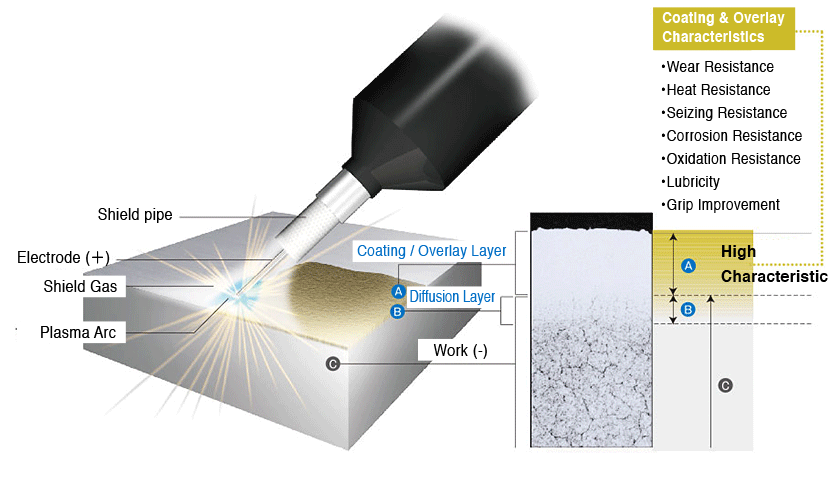

High Bonding Strength Mechanism:

A Depo Series device discharges direct current charged in the capacitor inside the main unit for a very short time of 10-6 to 10-5 seconds with a period of 10-3 to 10-1 seconds.

This heats the portion of the electrode material that is in contact with the workpiece to 8,000 to 25,000℃.

Then, the heated electrode material turns into plasma and metallurgically transfers to the workpiece surface. Next, the electrode material alloys with the surface, accumulates on it, and then spreads and enters under the surface, resulting in strong bonding.

Low Heat Input by adequate heat diffusion time

No occurring distortion, shrinkage, pin-holes, or stress

No occurring distortion, shrinkage, pin-holes, or stress

The Spark time is extremely short compared with the interval time so that no heat accumulation occurs during diffusion and deposition periods.

Extremely Strong Bonding by Solid Diffusion Layer

Electrode Material is deposited and alloyed to work surface forming a diffusion layer with penetration like grown roots.

This provides Strong Boding Coating and Overlay deposition without removing.

Shield Gas (Argon Gas etc.) prevents oxidation during processing, makes excellent quality Coating / Overlay possible.

| Applicable Substrates | Low and Medium carbon steels, Tool steels, Die and Mold steels, Cast steels, Stainless steels, Aluminum alloys, Copper alloys and the majority of alloys and composites having sufficient electrical conductivity |

|---|---|

| Alternatives | Plating, Thermal spray, CVD, PVD, TD treatment, Nitriding, Carburizing, Quench hardening, Welding, Carbides, Diamond, Lining etc. |

Tremendous On-site Workability

No required to dis-assembling large works, and processable only to necessary part

Portable and best fitable for On-site working. Processable only to necessary part and reducible finishing time.

No pre or post heating required. Significantly improve work efficiency.

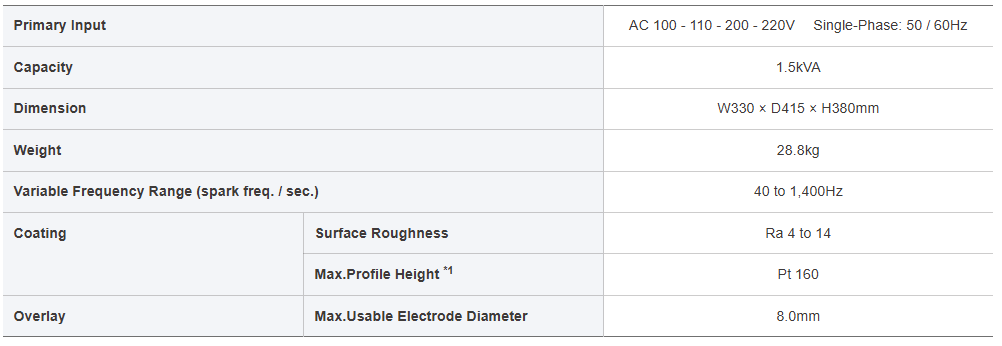

High processing capacity and Wide range adaptability

The thickness and surface roughness of the coating layer can be adjusted by the output and frequency, so processing can be performed as intended.

Since the overlay amount can be controlled in units of 0.1 mm, the amount of surplus is small and finishing time can be shortened. In addition, by using various applicators, it is possible to perform processing that suits the purpose.

Even if the processing parts are worn, they can be processed in layers from above.

Watch how TechnoCoat’s Depo Series makes overlay work smarter and faster: https://youtu.be/OleNKrZTNT8

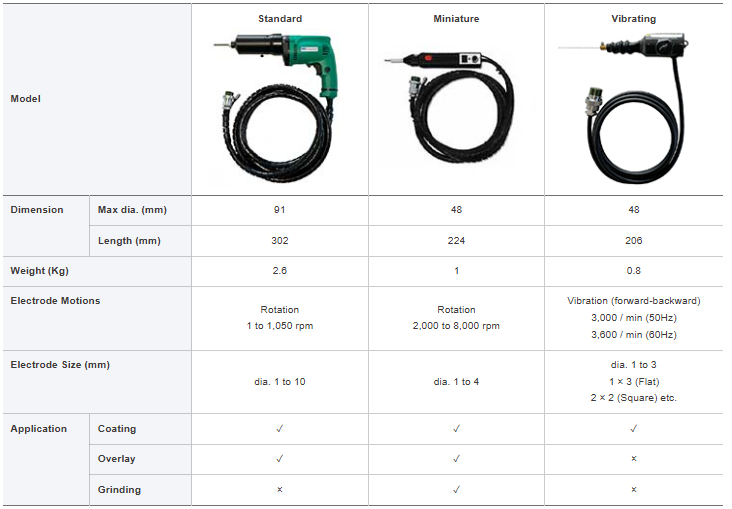

SparkDepo Specification

Contact Nam Sơn to receive a detailed quotation and consultation on the right laser solution for your business via hotline

Depo Series Applications

|

|

|

|

| Machine Parts and Equipment Overlay Repair at on-site |

Aluminum Diecast & Casting Products Overlay Repairing |

Rubber Tire mold (Aluminum Alloy) | Plastic Injection Mold (Large size) Overlay Repair |

|

|

|

|

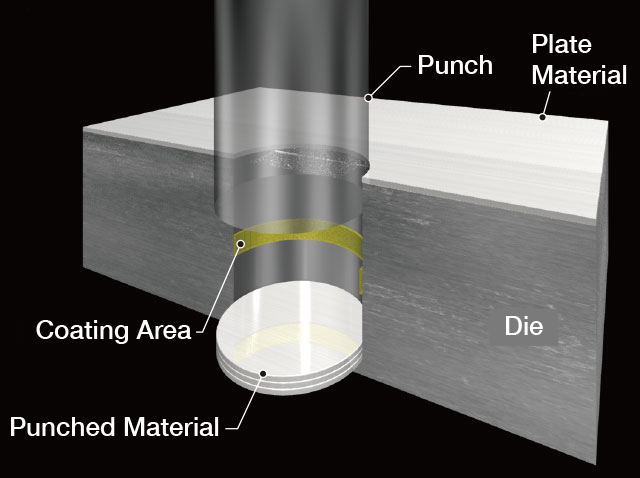

| Plastic Injection Mold Overlay Repairing (texturing) | Scum Riser Prevention for Press Die |

Aluminum Die Casting / Casting Preventive Maintenance and Defective Rates Reduction |

Coating Electrodes

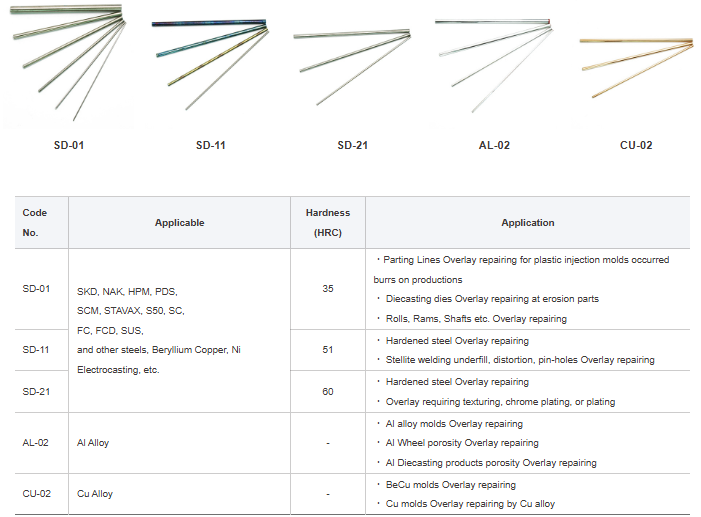

Overlay Electrodes

Applicators

RELATED PRODUCTS

see more productsThank for your attention to Depo Series – Digital SparkDepo. If you need get a quote, please fill in the form bellow & send it to us. We will respond within 24 hours.

If you have any question,

please fill in the form in the right

& send it to us.

We will respond to you in the shortest time.