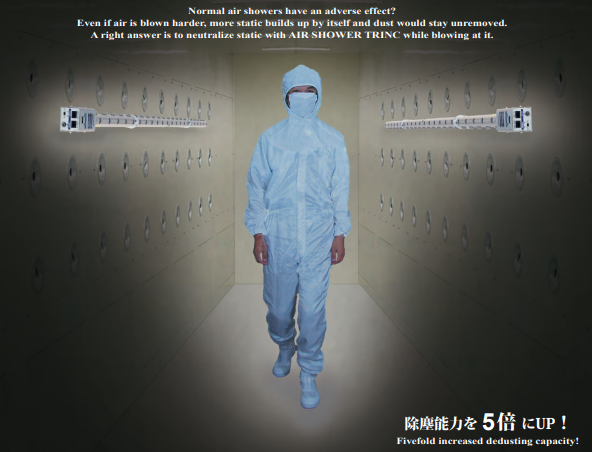

Anti-static bar device, installed for dust-free blow room TAS-331

The TAS-331 bar static eliminator is an effective solution for eliminating static electricity in industrial and manufacturing environments. Specifically designed for installation in clean dust, the TAS-331 helps ensure workspaces…

Details

- Tốc độ loại bỏ tăng lên gấp 3 đến 5 lần bởi các ion đậm đặc.

- Do điện áp cấp vào kim phóng điện thấp nên không xảy ra hiện tượng rò rỉ điện và có tuổi thọ cao.

- Có thể trang bị thêm mà không cần đục lỗ trên tường của hầm gió.

APPLICATION

INDUSTRIES

FUNCTION

MATERIAL

PRODUCT DESCRIPTION

The TAS-331 bar static eliminator is an effective solution for eliminating static electricity in industrial and manufacturing environments. Specifically designed for installation in clean dust, the TAS-331 helps ensure workspaces stay clean and power-free.

Features

- Bar Design: TAS-331 has a long bar design, making it easy to install in dust-free chambers and space-constrained areas.

- High Performance: Using modern discharge technology, TAS-331 generates large amounts of positive and negative ions, effectively eliminating static electricity.

- High Durability: Made from high quality materials, TAS-331 ensures stable and durable operation in harsh environments.

- Safe and Reliable: The device complies with international safety standards, ensuring safety for users and surrounding equipment.

Contact Nam Sơn to receive a detailed quotation and consultation on the right laser solution for your business via hotline

Advantage

- The removal rate is increased 3 to 5 times by concentrated ions.

- Because the voltage supplied to the discharge needle is low, no electric leakage occurs and has a long life.

- Can be retrofitted without punching holes in the wall of the wind tunnel.

Function

Eliminate Static Electricity:

Generates positive and negative ions to neutralize static charges on the surface of materials, preventing dust accumulation and problems caused by static electricity.

Improve Production Environment:

Specifically designed for dust-free chambers, the TAS-331 helps keep the workspace clean and dust-free.

Effective Ion Dispersion:

Using modern electric discharge technology to evenly disperse ions in a large space, ensuring optimal antistatic efficiency.

Electronic Device Protection:

Minimizes the risk of damage to sensitive electronic devices due to static electricity, extending the life of the device and increasing its reliability.

Minimize Manufacturing Errors:

Prevent errors related to static electricity and dirt during production, improving final product quality.

Safe and Easy to Use:

User-friendly design, easy to install and operate, ensuring safety during use.

Energy saving:

Uses low voltage to operate, helping to save energy and reduce operating costs.

With outstanding functions, the TAS-331 bar static eliminator is the ideal choice to improve the working environment and increase production efficiency.

Creates an environment where dust does not adhere to objects by eliminating dust’s static electricity.

Realizing a clean room without walls. All dust and particles lose static electricity.

“Why does dust stick to the product?” TRINC has focused on this fundamental question and analyzed its adhesion mechanism. As a result, we discovered that it was charged dust (activated dust) that adhered to the product. In other words, dust adhesion can be avoided by eliminating static electricity on dust deposited in space. We must avoid blowing air because it disperses dust and particles around. From here, TRINC’s idea of ”Clean room without walls = Clean room without walls” was born.

Thank for your attention to Anti-static bar device, installed for dust-free blow room TAS-331. If you need get a quote, please fill in the form bellow & send it to us. We will respond within 24 hours.

If you have any question,

please fill in the form in the right

& send it to us.

We will respond to you in the shortest time.